Products

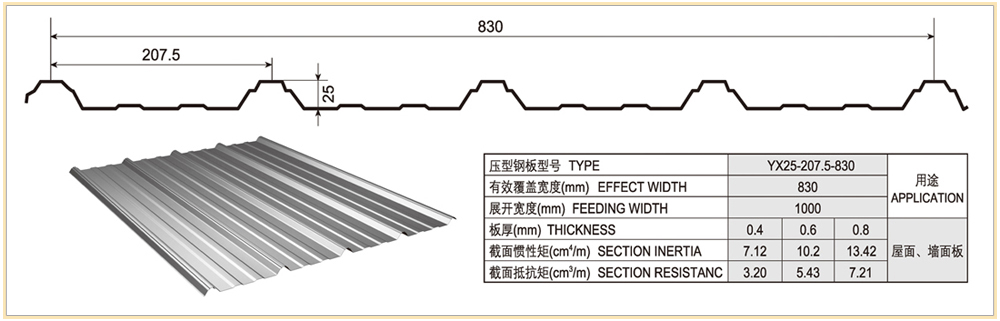

YX25-207.5-830 roof wall panel

The difference between the core materials of machine made board and manual board

keywords:

plate

purification

Category:

Various boards

Hotline:

- Detail

- Product Details

- Parameter

-

- Commodity name: YX25-207.5-830 roof wall panel

- Commodity ID: 1051924422937370624

The difference between the core materials of machine made board and manual board

The difference between the core materials of machine made board and manual board: the common core materials of machine made purification board include rock wool, foam, extruded board, glass wool, silicon core board, paper honeycomb, polyurethane, etc. The common core materials of manual cleaning board are rock wool, foam, extruded board, glass wool, silica plate, paper honeycomb, aluminum honeycomb, glass magnesium grid, etc. Width difference between machine board and manual board: the width specification of machine board is generally 950 and 1150, while the width of manual board can be arbitrarily determined according to the construction situation, and the width can reach 1180. Thickness difference between machine board and manual board: there are many thickness specifications of manual board, while the thickness specifications of 50, 75, 100, 150, 200 and 250 machine boards are relatively small. From the above specifications, we can see that there are only 50, 75, 100 and 150. Compared with the machine board, the manual board is more selective and more convenient for design and installation. Core materials can be selected.

In brief, the purification plate is made of color coated plate, color steel plate, stainless steel and other materials, and coated with a layer of chemical coating on its surface to make its surface smooth, anti-static, antibacterial and other effects. It is widely used in purification engineering fields with strict requirements for indoor environment, such as electronics, pharmaceuticals, food, biology, aerospace, instrument manufacturing, scientific research, etc. The use of ordinary color steel plate is not particularly strict.

PP board is called purification board because it has the advantages and practicability of purification board; Advantages of PP board:

1. High hardness and melting point.

2. Low thermal deformation temperature (100), low transparency, low gloss and low rigidity.

3. High impact strength. The strength of polypropylene increases with the increase of ethylene content.

4. The purification plate has excellent moisture resistance, acid and alkali corrosion resistance and solubility resistance.

5. The shrinkage rate of PP board is very high. Because PP plate is semi-crystalline material, the shrinkage rate is generally 1.8~2.5%. The directional uniformity of shrinkage is much better than PE-HD and other materials.

Key words:- plate

- purification

-

Previous

Previous

Related products

Online Message

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible