Products

Decoration keel

Carbon fiber foam sandwich panel is a sandwich structure composed of panel and core material.

keywords:

panel

sandwich

Category:

Decoration keel

Hotline:

- Detail

- Product Details

- Parameter

-

- Commodity name: Decoration keel

- Commodity ID: 1051924703800549376

Carbon fiber foam sandwich panel is a sandwich structure composed of panel and core material.

Carbon fiber foam sandwich panel is a sandwich structure composed of panel and core material. Its panel has high strength and rigidity, but its thickness is thin; The strength and rigidity of the interlayer are low, but the thickness is relatively thick. For sandwich structure, in order to improve the structural efficiency, it is necessary to make full use of the bearing capacity of the panel. In fact, when sandwich panels are used as structural elements, the high ratio of bending stiffness to mass is fully utilized.

(1) Improve the extrusion strength of the panel in the connection area. At the connection part of the connection area, the reinforcement shall be appropriately increased according to the load to improve the extrusion strength of the hole edge. The reinforcement of the laminated slab shall be laid at 45 ° with the load direction.

(2) Reduce the extrusion load at the edge of the panel hole. The stiffener method can be used at the connection of foam sandwich panels to distribute most of the load to the panel through the bonding surface, so as to reduce the extrusion stress at the edge of the panel hole.

(3) Avoid separate connection with the upper panel or lower panel. During mechanical connection, it shall be avoided to connect with only one panel separately to prevent the adhesive layer between the panel interlayer from peeling off and damage due to the tension of the connecting nail. Therefore, for the connection of foam sandwich panel sandwich structure, the connecting nail should be fixed with the sandwich, and the tension of the nail should be borne by the shear force of the sandwich.

It can be seen that with the thickening of the carbon fiber composite panel layer or foam sandwich panel, the curve slope decreases, the carbon fiber composite stiffness of the foam sandwich panel structure is better, and the critical point is more and more backward. The thickness of the carbon fiber composite panel layer plays a decisive role at the critical point. Sinosteel Star (Xiamen) New Material Technology Co., Ltd. is mainly engaged in the trade of steel products and the processing and manufacturing of steel structure materials. Its main products include: color steel baffle, rock wool sandwich panel, site enclosure, galvanized plate, foam sandwich panel, construction enclosure, sandwich panel, purification panel, purlin, color steel plate, profiled plate, steel structure, aluminum magnesium manganese plate, fire insulation plate, etc. New and old customers are welcome to discuss cooperation.

Key words:- panel

- sandwich

-

Introduce

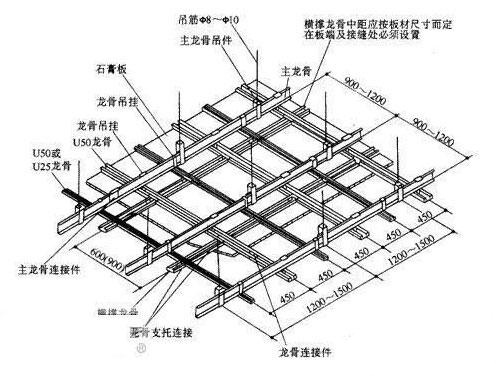

Light steel keel is a metal framework for construction, which is made of high-quality continuous hot-dip galvanized sheet and strip as raw material and rolled by cold bending process. It is used for modeling decoration of non-load-bearing walls and building roofs with paper-faced gypsum board, decorative gypsum board and other lightweight panels as finishes. It is applicable to the molding decoration of various building roofs, the internal and external walls of buildings and the basic materials of the scaffolding ceiling.

Type

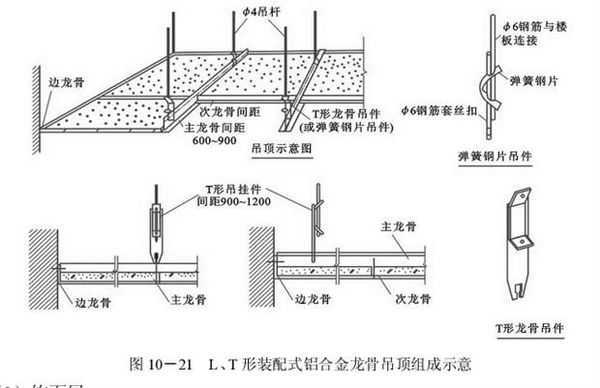

The light steel keel includes ceiling keel and partition keel according to its purpose, and V-shaped, C-shaped, T-shaped, L-shaped and U-shaped keels according to its section form.

The marking sequence of light steel keel is: product name, code, width and height of section shape, steel plate thickness and standard number. If the section shape is "C" type, the width is 50mm, the height is 15mm, and the thickness of steel plate is 1.5mm, the ceiling keel is marked as: light steel keel for building.

Appearance quality The shape of light steel keel shall be flat, the edges and corners shall be clear, and the cut shall not have burr and deformation that affect the use. The zinc coating shall be free of peeling, burring, peeling and other defects. For defects such as corrosion, damage, black spot, pitting, etc., when tested according to the specified method, they shall comply with the provisions of Table 2-81. During appearance quality inspection, visual inspection shall be carried out under the condition of bright light 0.5m away from the product. The surface of light steel keel shall be galvanized and rust-proof, and the amount of double-sided galvanizing shall not be less than 120g/m for superior products

Painted keel

The painted keel is made of fireproof galvanized sheet, which is durable. It adopts economical placement structure, special connection method and combined loading and unloading. Convenient, time-saving and simple construction. The keel surface is made of galvanized steel plate, which has been painted.

The difference between the light steel keel and the painted keel is that the general light steel keel does not need to be coated, and the coating (galvanized) is made, while the painted keel surface has been painted, generally black and white, and a few of them are baked into other colors according to the design requirements, mainly because the painted keel is mostly used for the exposed keel, and the painted keel is to ensure that the exposed part will not affect the appearance if it is not rusted.

Open frame keel

Plane series, groove series, three-dimensional groove series. Concealed keel: plane series

The overall plane effect of the painted keel is good, the lines are simple and beautiful. The painted keel is safe, firm and beautiful, suitable for supporting construction of various mineral wool ceilings, aluminum square ceilings, calcium silicate boards, etc. It has the advantages of light weight, high strength, waterproof, fireproof, shockproof, soundproof, sound-absorbing and so on. At the same time, it also has the advantages of short construction period and simple construction. It is a new type of ceiling decoration material, which is widely used in shopping malls, hospitals, banks, hotels, factories, terminal buildings, etc.

The main specifications of partition keel are Q50, Q75 and Q100.

The main specifications of ceiling keel are D38, D45, D50 and D60.

standard

The decisive factors for the quality of light steel keel:

1. High quality steel strip;

2. Light steel keel forming equipment;

3. Thickness deviation of light steel keel steel strip;

4. Galvanizing quantity of light steel keel on both sides;

5. Appearance quality;

6. Fine management of keel manufacturer.

Appearance quality The shape of light steel keel shall be flat, the edges and corners shall be clear, and the cut shall not have burr and deformation that affect the use. The zinc coating shall be free of peeling, burring, peeling and other defects. During appearance quality inspection, visual inspection shall be carried out under the condition of bright light 0.5m away from the product. The surface of light steel keel shall be galvanized and rust-proof, and the amount of double-sided galvanizing shall not be less than 120g/m for superior products

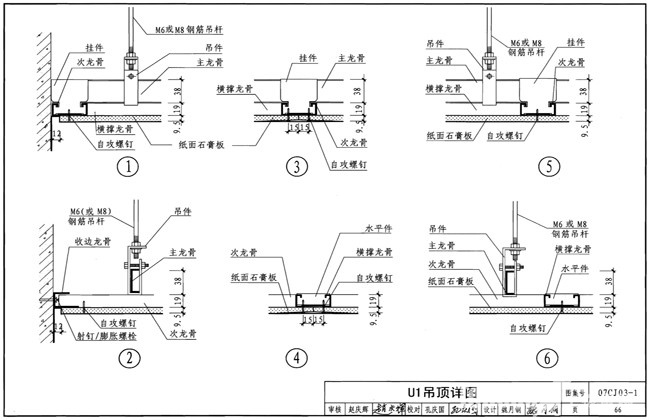

Installation method

Snapping line

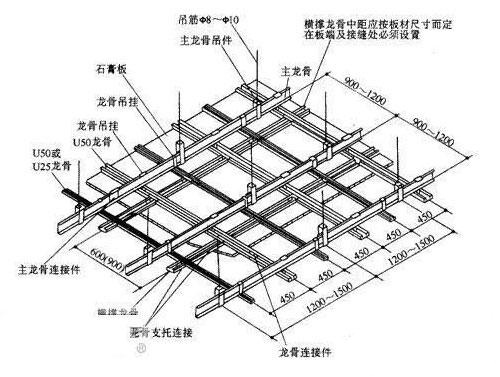

Use a level gauge to mark horizontal points on the corner of each wall (column) in the room (if the wall is long, a few points in the middle are also appropriate), and snap the level line (the level line is generally 500mm from the ground). Measure from the level line to the design height of the ceiling plus 12mm (the thickness of a layer of white bone plate). Use a chalk line to mark the level line along the wall (column), which is the lower skin line of the secondary keel of the ceiling. At the same time, according to the ceiling plan, the position of the main keel shall be popped out on the concrete roof. The main keel shall be divided from the center of the ceiling to both sides with a maximum spacing of 1000mm, and the fixed points of the suspender shall be marked with a spacing of 900-1000mm. If the fixed point of beam and pipe is larger than the design and specification requirements, the fixed point of suspender shall be added.

Fixed hanging rod

Use expansion bolts to fix the suspender. The length of the suspender is less than 1000mm, which can be used φ 6. If it is 1000mm larger, it should be used φ 8. The suspender shall also be provided with reverse support. The suspender can adopt cold-drawn reinforcement and coiled reinforcement, but the coiled reinforcement shall be straightened by machinery. The length of the suspender is less than 1000mm, which can be used φ 8. If the suspender is larger than 1000mm, the user shall take φ 10. The suspender shall also be provided with reverse support. One end of suspender is the same as L30 × thirty × 3 Angle code welding (the hole diameter of the angle code shall be determined according to the diameter of the suspender and expansion bolt), and the other end can be tapped out of a screw rod larger than 100mm, or the finished screw rod can be purchased for welding. The fabricated suspender shall be subject to anti-rust treatment. The suspender shall be fixed on the floor with expansion bolts and punched with an impact hammer

Hanging rod on beam

1) Hanging rods shall be straight and have sufficient bearing capacity. When the embedded rod needs to be extended, it must be overlapped and welded firmly, and the weld should be even and full.

2) The distance between the suspender and the end of the main keel shall not exceed 300mm, otherwise the suspender shall be added

3) Additional suspenders shall be set for ceiling lamps, air vents and access openings.

Precautions for installation of V-shaped suspended keel

1. When used for ceiling, the long side of the gypsum board must be laid vertically or horizontally with the auxiliary keel. The distance between the fixing parts (self-tapping screws) and the gypsum board is about 10-16 mm. When fastening, the gypsum board must be fastened with the skeleton;

2. When fixing the plate, the long side and short side of the middle of a plate shall be fixed. After the nail is positioned, the nail head shall be slightly embedded in the plate, but the plate surface shall not be damaged;

3. The gypsum board shall be closely connected, and the joint must be provided with a transverse brace keel. The gypsum board shall be installed in a stress-free state, and shall not be positioned under strong pressure. The bottom surface of the auxiliary keel shall be in the same plane, and the connection part of the keel extension shall be staggered.

The painted keel is made of cold-rolled continuous hot-dip galvanized steel strip and painted strip as raw materials, and is a thin-walled section with reasonable "T" section structure through cold bending process and composite rolling.

Install side keel

The installation of side keel shall be in accordance with the design requirements, and the L-shaped galvanized light steel strip shall be fixed on the embedded wooden brick with self-tapping screws along the horizontal keel line on the wall (column); If it is a concrete wall (column), it can be fixed by shooting nails. The spacing of shooting nails should not be greater than the spacing of the secondary keel of the ceiling.

Install the main keel

1) The main keel shall be hung on the suspender. The distance between main keels is 900~1000mm. The main keel is divided into light steel keel and T-shaped keel. Light steel keel can choose UC50 medium keel and UC38 small keel. The main keel shall be installed parallel to the long direction of the room, and shall be arched at the same time. The height of arched shall be 1/200~1/300 of the room span. The cantilever section of the main keel shall not be greater than 300mm, or the suspender shall be added. The main keel shall be extended by butt joint, and the butt joints of adjacent keels shall be staggered. The main keel shall be basically leveled after hanging.

2) For the ceiling with a span of more than 15m, a large keel shall be added on the main keel every 15m, and the vertical main keel shall be welded firmly.

3) If there is a large molding ceiling, the molding part shall be welded into a frame with angle steel or flat steel, and shall be firmly connected with the floor.

Installation of secondary keel

The secondary keel is divided into two types: keel and dark keel. Concealed keel ceiling: when installing the cover plate, the secondary keel is enclosed in the shed, and the secondary keel is not visible on the ceiling surface. Open keel ceiling: that is, when installing the cover plate, the secondary keel is exposed under the cover plate, and the secondary keel can be seen on the ceiling surface. The secondary keel shall be installed close to the main keel. The distance between secondary keels is 300~600mm. The secondary keel is divided into T-shaped painted keel, T-shaped aluminum alloy keel, and special keel equipped by various strip gusset manufacturers. When the secondary keel is fixed on the main keel with the T-shaped galvanized iron sheet connector, the two ends of the secondary keel should be placed on the horizontal flange of the L-shaped side keel, and the strip gusset plate has a special internal corner line as the side keel.

R&D products

V-shaped hanging keel light steel keel

V-shaped hanging keel, also known as card keel, has the national decoration material patent number (main dragon-ZL002 63956.4; auxiliary dragon-ZL003 34437.1). In terms of design and manufacturing, it breaks the traditional form of ceiling keel, and uses high-quality snowflake boards as raw materials. It has strong fireproof, rust proof and anti-aging properties. All functions have passed the national test (GB11981-2001). It is easy to construct and has excellent effects, and is widely used in modern decoration projects.

The two sides of the V-shaped groove are symmetrically and orderly equipped with anchor hooks, which can form an English or metric combination with the auxiliary keel. The connection between the main keel and the auxiliary keel needs to be locked with 8 cm screws to make it more firm and durable.

Light steel keel of partition wall

Light steel keel is widely used in luxury villas, high-end hotels, office buildings and shopping malls. It is strong, durable, and corrosion resistant. It is also widely welcomed by the construction unit and the construction unit in terms of price. It reduces the worries about the quality of the project during the construction process and the frequent maintenance caused by the material quality problems during the use process, and greatly reduces the construction cost of the project and the various troubles caused by the maintenance during the use.

The thickness of the light steel keel is also very important. It plays a key role in the bearing capacity of the wall. In large luxury hotels and office buildings, the light steel keel is mostly used as the partition wall; In the decoration design of the hotel rooms, the partition wall between the bathrooms and the guest rooms in most guest rooms is very important to bear the weight, because on the side of the guest rooms, the general design uses wallpaper and emulsion paint, and the decorative materials on the single wall are lighter than the weight of crops.

-

Related products

Online Message

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible