Products

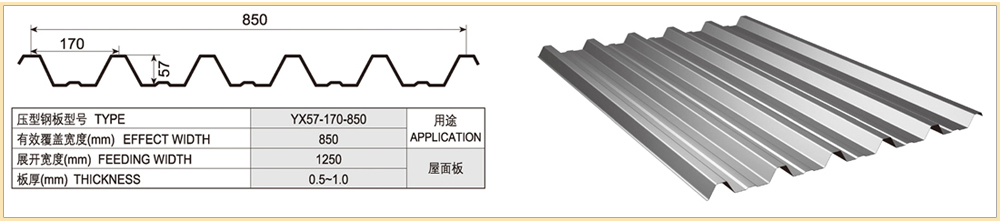

YX57-170-850 roof wall panel

During installation, be familiar with the drawings, understand the plane layout, and understand the relationship between the purification board and the building.

keywords:

roof

plate

Category:

Various boards

Hotline:

- Detail

- Product Details

- Parameter

-

- Commodity name: YX57-170-850 roof wall panel

- Commodity ID: 1051924376133132288

During installation, be familiar with the drawings, understand the plane layout, and understand the relationship between the purification board and the building.

During installation, be familiar with the drawings, understand the plane layout, and understand the relationship between the purification board and the building.

The secondary plate layout is an important step in the prefabrication and installation of the purification plate. It is to convert the design drawing into the intermediate conversion drawing. The secondary processing is carried out in the factory. The standard plate is made into different types of wall panels, which are combined to reflect the design intent. The standard plate is made in the purification plate factory and can be assembled at the construction site. It can ensure the firmness of the wallboard and accelerate the installation speed of the purification board. During the factory prefabrication, the gap and installation allowance between the door opening, window opening and joint are fully considered according to experience.

During the whole process of transportation, manufacturing and installation, avoid scratches, heavy pressure and surface impact to prevent pits and scratches that cannot be corrected. The plastic protective film on both sides of the purification plate can only be removed after installation and cleaning. The setting-out work before the installation of the purification board should be carried out after the completion of the ground (building) surface and only when other relevant installation conditions are met. For example, the large equipment has been delivered in place, the concealed ground pipeline has been adjusted, and the main installation work of the technical interlayer has been basically completed.

After we bought the purification board, how to store it? What should we pay attention to?

1. When the product arrives, check the quality, length, quantity, transportation damage, etc. If any damage is found, please indicate it on the receipt, ask the driver to sign and provide a description of the damage.

2. When unloading by machinery, the truck shall be unloaded on a solid and flat ground. When the fork is in contact with the plate, the surface should be covered with a layer of soft cushion or backing plate to avoid damage to the plate.

3. Wear protective gloves during manual unloading and handling to avoid surface wear. Lift and handle with care, lift the bottom with both hands, and do not lift the top plate separately to avoid tearing the plate; Do not drag to avoid wearing or scratching the panel; Avoid bending the plate, otherwise the filling material inside the plate will break and the surface of the plate will deform.

Precautions for stacking: 1. The products shall be stored on a solid and flat ground and in a ventilated and light-proof place to avoid the sun. When the product is placed outside the workshop, appropriate protective measures shall be taken to avoid the sun and rain. 2. Obvious signs shall be set around the crib to avoid collision and damage; Do not place heavy and hard objects on the purification plate stack to avoid scratching the surface; No trampling.

Key words:- roof

- plate

-

Previous

Next

Previous

Next

Related products

Online Message

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible