Products

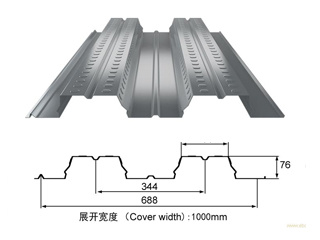

YX75-200-600 (open type)

keywords:

floor

plate

Category:

Galvanized floor board

Hotline:

- Detail

- Product Details

- Parameter

-

- Commodity name: YX75-200-600 (open type)

- Commodity ID: 1051925329506820096

Floor bearing plate, floor plate, floor plate and steel bearing plate refer to profiled steel plate not only as the permanent formwork of concrete floor slab, but also as the lower load-bearing reinforcement of the floor slab to participate in the force calculation of the floor slab, and work together with the concrete to form a composite floor slab. (1) (2) (3) The rigidity of the composite floor is large (4) The construction is convenient and fast (5) It is easy to update (6) The structural requirements for the industrial production of the composite floor (1) The profiled steel plate of the composite floor should be galvanized steel plate, and the thickness of the galvanized layer should also meet the requirements of not causing rust damage during the service period. (2) The average width of the wave groove for concrete pouring shall not be less than 50mm. When stud connectors are set in the groove, the total height of the composite floor shall not be greater than 80mm. (3) The thickness of composite plate shall not be less than 90 mm; The thickness of concrete above the top of profiled steel plate shall not be less than 50mm.

Key words:- floor

- plate

-

(4) Anchorage requirements: stud anchors shall be set at the end of the composite plate. The stud shall be set at the concave rib of the profiled steel plate of the end support, penetrate the profiled steel plate and weld the stud and steel plate firmly on the steel beam. (5) The supporting length of the profiled steel plate in the composite plate on the steel beam shall not be less than 50mm. The bearing length on the masonry shall not be less than 75mm. Performance of composite floor slab: save a lot of temporary formwork, omit all or part of the formwork support, reduce the concrete consumption, reduce the permanent load of the structure, which is more important for high-rise buildings and seismic areas, save a lot of labor in transportation, stacking and installation, reduce the workload, facilitate the laying of communication, power, heating and other pipelines, and can lay thermal insulation, sound insulation, heat insulation Vibration isolation and other materials. Improve the floor performance and give full play to the good tensile strength and ductility of steel and the excellent compressive strength and greater rigidity of concrete

Other names

Composite floor, floor bearing plate, steel bearing plate, profiled steel plate, floor plate, steel floor bearing plate, composite floor plate, galvanized steel bearing plate, galvanized floor plate, galvanized floor bearing plate, composite floor bearing plate, composite floor plate, floor steel bearing plate, building profiled steel plate, composite floor, etc., which are also divided into: open floor bearing plate, fully closed floor bearing plate, dovetail floor bearing plate (also called retracted floor bearing plate), etc

main features

1: Adapt to the requirements of rapid construction of the main steel structure, provide a firm working platform in a short time, and adopt the flow construction of laying profiled steel plates on multiple floors and pouring concrete slabs in layers.

2: In the use stage, the floor bearing plate is used as the tensile reinforcement of the concrete floor slab, which also improves the rigidity of the floor slab and saves the amount of reinforcement and concrete.

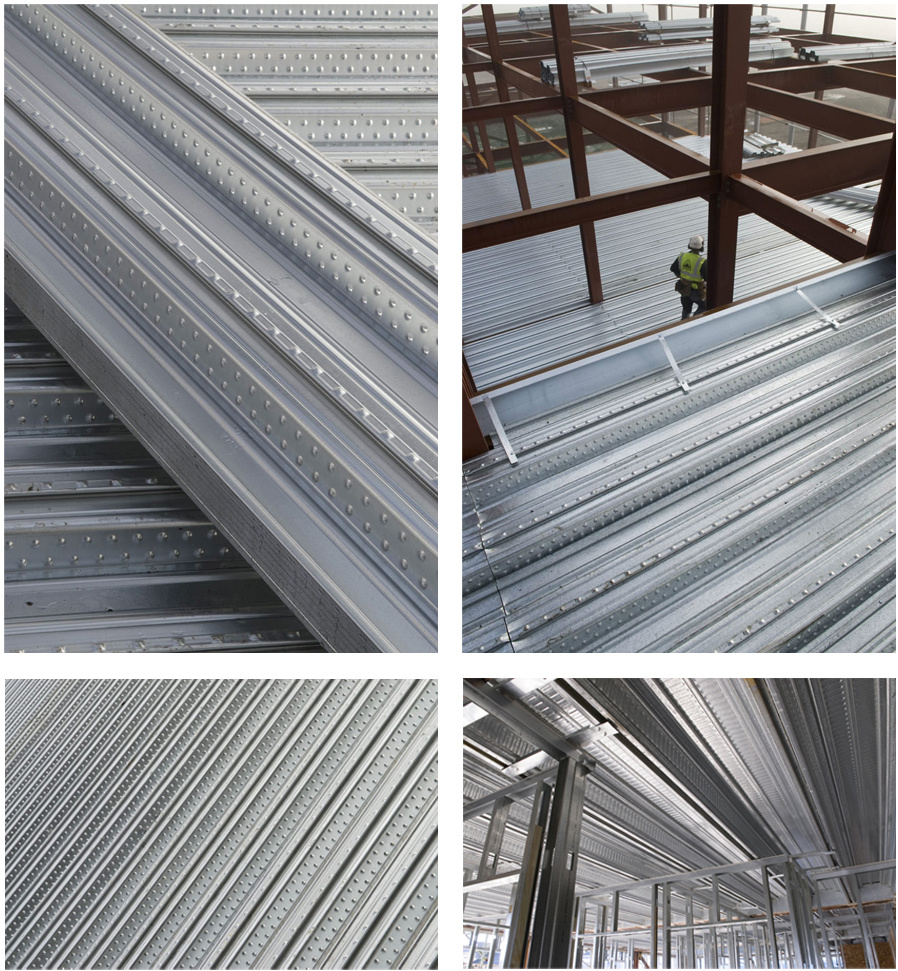

3: The embossing on the surface of the profiled plate makes the maximum binding force between the floor bearing plate and the concrete, so that the two form a whole, with stiffening ribs, so that the floor bearing plate system has high strength bearing capacity.

4: Under cantilever condition, the floor bearing plate is only used as permanent formwork. The cantilever length can be determined according to the section characteristics of the floor bearing plate. In order to prevent the cracking of the cantilever slab, negative reinforcement shall be provided at the support according to the design of the structural engineer.

5: The floor bearing plate of our company has passed the fire resistance limit test of the national fixed fire extinguishing system and the fire resistance component quality testing center. As a composite floor bearing plate, there is no need for fire protection spraying, which greatly reduces the project cost.

Product application

The products are widely used in the construction of steel structures such as power plants, power equipment companies, automobile exhibition halls, steel structure workshops, cement warehouses, steel structure offices, airport terminal buildings, railway stations, stadiums, concert halls, grand theatres, large supermarkets, logistics centers, Olympic venues and stadiums.

Product testing

A. Dynamic load test: the qualified floor bearing plate needs to undergo several groups of dynamic load tests to obtain the shear - bond coefficient of the composite plate, test the bonding capacity of the floor bearing plate and concrete, and obtain the design load it bears on the large span.

B. Fire-resistance test: three groups of floors were used to carry out 1.5 hours, 2 hours and 3 hours of loading fire resistance test in the fire resistance laboratory, and the temperature distribution in the floor was measured at the same time to test whether the floor bearing plate met the thermal insulation requirements, and the positive bending moment resistance in the fire resistance stage.

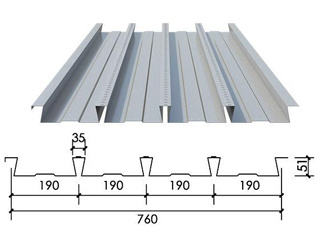

Installation process

The construction process flow of the floor bearing plate is generally as follows: snapping the line → clearing the plate → lifting → arranging the plate → cutting → pressing → side welding → end welding → hole reservation → plugging → acceptance → stud → reinforcement → embedded parts → pouring → curing. Of course, so many processes are inseparable from good labor organization. The following processes can also be handled separately according to the actual situation on the site. The labor organization should be divided into two groups,

The first group is responsible for transporting materials, including material cleaning and reshipment, until the floor bearing plate is hoisted to the construction site accurately according to the construction progress, including 5 lifting workers;

The second group is responsible for laying, including reinforcement arrangement, cutting, installation and hole reservation. Every three people are in a group, responsible for one section, and four groups work in the same operation layer at the same time. During the next process of binding reinforcement and pouring concrete, special personnel shall be assigned to strengthen the maintenance of the floor bearing plate. The specific approach is:

(1) First, snap the center line of the steel beam in the planking area. The center line of the main beam is the control line of the fixed position of the floor support plate. The overlapping width of the floor bearing plate lapping steel beam is controlled by the center line of the main beam, and the welding spot position of the floor bearing plate and steel beam is determined. The center line of the secondary beam will determine the welding position of the penetration welding stud. Because it is difficult to observe the specific position of the secondary beam flange after the floor bearing plate is laid, the centerline of the secondary beam and the width of the secondary beam flange should be rebounded on the centerline of the main beam. When fixing the stud, the centerline of the secondary beam and the width of the secondary beam flange should be rebounded on the floor bearing plate on the secondary beam surface.

(2) The floor bearing plate shall be cleaned in layers and zones in the stockyard according to the material list, and the number shall be marked, the layer, zone and number shall be clearly distinguished, and marked with a marker, and transported to the designated construction site accurately.

(3) Special soft sling shall be used during lifting to ensure that the floor bearing plate plate is not deformed as a whole and not crimped locally. The installation process of three floors and one section of column is generally adopted for multi-layer steel structure design. (For single-layer steel structure, it is needless to say) The installation of floor bearing plate shall be carried out simultaneously with the steel structure column and beam, and the difference shall be at least three floors. Therefore, when lifting the floor bearing plate, it can only be put through the upper beam and column, and the lifting worker should be controlled between the beams and columns by layers.

(4) The plasma cutter or plate shearer shall be used to cut the edges and corners. The margin during cutting and setting out shall be controlled within 5mm. Measures shall be taken to prevent slurry leakage during concrete pouring.

(5) The connection between the floor bearing plate and the side plate of the floor bearing plate shall be pressed with a seaming pliers, so that the single floor bearing plate can be connected into a whole plate. First spot weld the side of the floor bearing plate, then fix the ends, and finally fix them with studs.

(6) Strengthen concrete curing.

matters needing attention

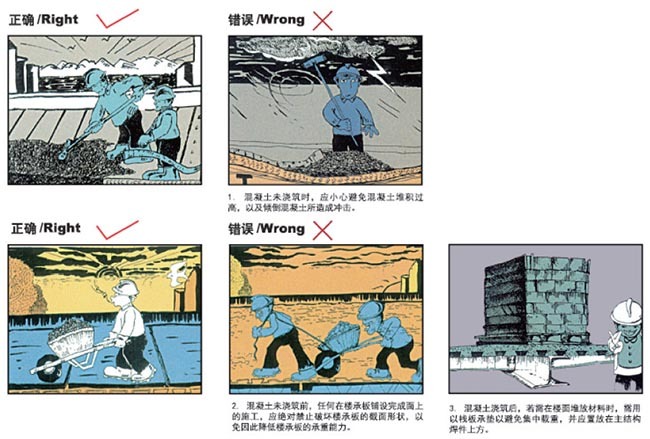

The spacing of steel structure column grid is generally 5~9.0m × 8~15m, the secondary beam spacing is 3m, and the blanking length of the floor bearing plate is 4.97~8.97m, which is difficult to transport and install. Especially, it is difficult to vertically lift the floor bearing plate from the arc area, and it is difficult to wear the sleeve between the secondary beam narrow from top to bottom, and it disrupts the normal welding process of the secondary beam. If the cutting length is controlled to be 3~6m, the problem that it cannot be lifted between secondary beams during vertical transportation can be avoided. Special soft sling shall be used for lifting the floor bearing plate. During each hoisting, check whether the soft sling is torn or cut. The probe shall be prevented when the floor bearing plate is placed on the steel beam. During paving, the operator shall fasten the safety belt and ensure that it is fixed on the surrounding safety rope while paving. The welding shall be connected by penetration spot welding. Before welding, the arc striking test welding of leftover materials shall be prepared, and the welding current shall be adjusted. Because there is no horizontal formwork and vertical support at the bottom of the floor bearing plate, the cloth shall not be too concentrated when pouring concrete, and the plate vibrator shall be used to timely share the vibration.

Precautions during construction

Infrastructure

The floor bearing plate profile is 0.8mm thick, 1.0mm thick, 1.2mm wide, 688mm~940mm wide, and 51 mm~76mm high. The project floor bearing plate and reinforced concrete structure act together to form a composite structure. The floor bearing plate is laid and connected with the steel beam, the plate end is welded with the steel beam by penetration spot welding, and the middle is welded with the stud and the steel beam by penetration fusion welding; The floor bearing plates are connected with special clamping pliers for clamping and pressing holes; The plug shall be spot welded with the floor bearing plate and steel beam with the special galvanized plug plate. If the floor bearing plate with arc area is cut by plasma cutting machine, the cut is smooth and the surface zinc coating is complete. The floor bearing plate shall be welded by manual arc spot welding. The electrode is E4303, with a diameter of 3.2 mm, and the penetration welding point is 16 mm. The original design welding point spacing is 305 mm, and then the welding point is doubled to ensure that the floor bearing plate does not deform when the operator walks, and the end of the floor bearing plate does not leak when the concrete is poured. When the structural elevation of the floor layer changes inconsistently, the measures of welding section steel shall be taken to make the horizontal structure form a step transition. When the elevation is reduced, the I-beam web shall be welded with angle steel; When raising the elevation, the I-beam flange shall be welded with channel steel. When there are reserved openings on the floor, the size is generally greater than 500mm × When 500mm, the first opening measure shall be adopted, that is, the steel beam shall be separated by welded steel joists to increase the rigidity of the opening, and the mesh reinforcement shall be disconnected at the opening and welded with the section steel; The hole size is less than 500mm × When 500mm, the post-opening measures shall be taken, that is, add a plug partition plate on the floor bearing plate, the mesh reinforcement shall be connected, and the reinforcement can be cut after the concrete is poured and formed

usage method

The third generation of steel bar truss floor support plate is a composite formwork that uses imported equipment to process the steel bar in the floor into steel bar truss in the factory, and weld the steel bar truss and galvanized steel plate into a whole in the factory. The formwork system combines the reinforcement in the concrete floor with the construction formwork to form a load-bearing component that can bear the dead weight of wet concrete and construction load during the construction phase, and the component can be used as the lateral support of the steel beam during the construction phase. In the service stage, the steel truss and concrete work together to bear the service load.

1. The stress mode and combination mode of the truss floor are reasonable, with the overall rigidity of the cast-in-place concrete, which can easily complete the construction and use of the two-way slab, while the lower skin of the ordinary profiled slab is perpendicular to the rib direction and the reinforcement cannot be part.

2. In the construction, the beam spacing is more than 3 meters, and the ordinary profiled plate basically needs to be provided with temporary support; The maximum unsupported spacing of reinforcement truss formwork can be more than 5 meters.

3. Temporary openings are made on the truss formwork, basically without reinforcement, and the laying of machine wires and pipes is convenient

4. The steel plate does not participate in the stress, does not need fire-resistant and anti-corrosive coating, and does not need to worry about the repair problem after the fire. It is safe and economical. The plate bottom is flat, the clear height is guaranteed, the two-way stiffness of the floor is consistent, and the seismic performance is good. It solves the two-way reinforcement problem of the closed plate, and the reinforcement spacing and the thickness of the concrete protective layer are guaranteed

5. The two-way slab design and construction is simple, suitable for large-span workshops, with reasonable coating, reliable stud welding quality, no need for penetration welding at the end, and good shear resistance of the floor

-

Floor bearing plate, floor bearing plate model: floor bearing plate specification: YX51-342-1025 open floor bearing plate/steel bearing plate, YX75-230-690 floor bearing plate, YX75-200-600 (7520 type, galvanized profiled steel plate), YX75-293-880 (with indentation profiled steel plate), YX76-344-688 (common steel bearing plate), YX75-230-690 floor bearing plate, YX76-305-915 floor bearing plate, 315 floor bearing plate (new plate type developed by Shandong Hongxinyuan), YX65-185-555 (full closed profiled steel plate), YX51-200-600 (dovetail type floor bearing plate), YX51-226-678 floor bearing plate, YX51-253-760 steel bearing plate, YX51-250-750 floor bearing plate, YX51-240-720 steel bearing plate, YX51-305-914 floor bearing plate, YX50-180-720 floor bearing plate, YX35-125-750 profiled steel plate, YX51-330-992 floor bearing plate, etc.

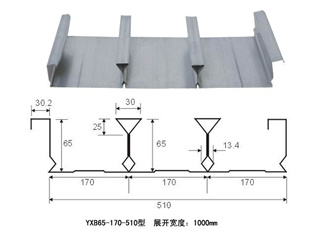

Shrinkage combined floor yx51-190-760

yx65-170-510

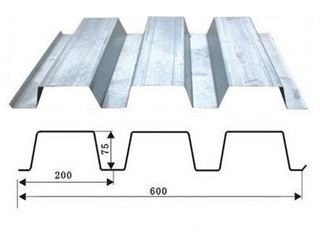

Yx75-200-600 (open type)

yx76-344-688

Related products

Online Message

*Note: Please fill in the information accurately and keep the communication unblocked. We will contact you as soon as possible